News & Blogs

Essential Tips for Using Reefer Shipping Containers for Safe Transport

In the world of logistics, the safe transport of temperature-sensitive goods is paramount, and reefer shipping containers have emerged as a vital solution. Industry expert Dr. Emily Hartman, a seasoned logistics consultant, emphasizes the importance of these containers, stating, "Using reefer shipping containers effectively not only preserves perishable products but also maintains their quality and safety during transit." With the global demand for fresh and safe products continually rising, understanding how to utilize reefer shipping containers becomes essential for businesses involved in the transport of fruits, pharmaceuticals, and other temperature-sensitive items.

The intricate design and technology of reefer shipping containers allow for precise temperature regulation, which is crucial in preventing spoilage and ensuring compliance with health standards. In this evolving landscape, logistics providers must familiarize themselves with best practices in handling these containers. Armed with knowledge about loading procedures, temperature monitoring, and maintenance, businesses can navigate the complexities of cold chain logistics, ultimately leading to successful and efficient delivery.

As we explore the essential tips for using reefer shipping containers for safe transport, it becomes clear that investing time in education and proper practices not only secures the integrity of the shipments but also enhances customer satisfaction and operational efficiency. Adopting these strategies will prove beneficial for anyone engaged in the transport of perishable goods.

Understanding Reefer Shipping Containers and Their Importance

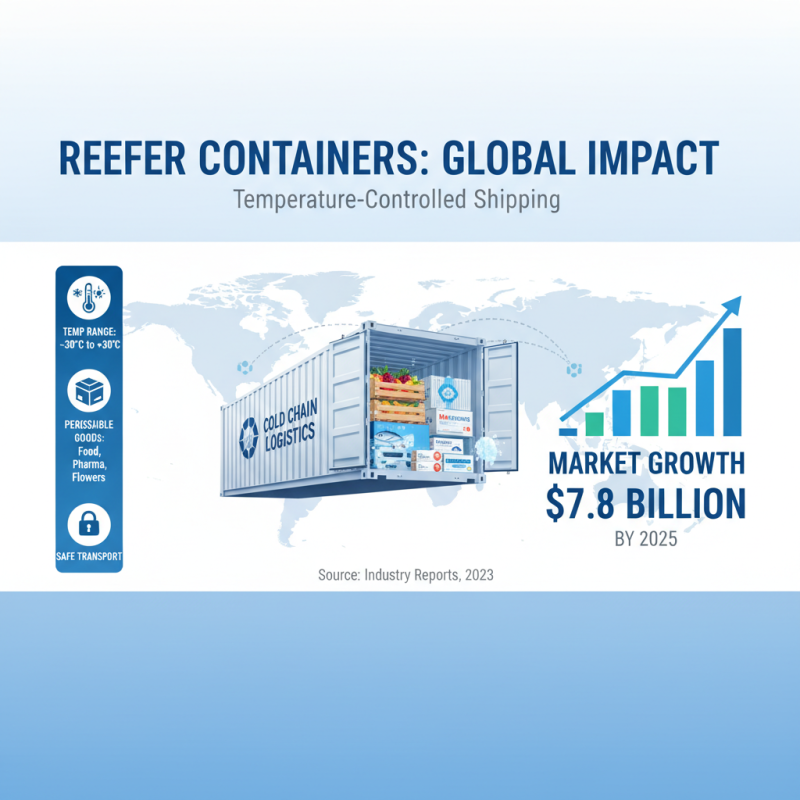

Reefer shipping containers, also known as refrigerated containers, play a critical role in the global supply chain, especially for perishable goods. These specialized containers maintain a consistent temperature, allowing for safe transport of items such as fruits, vegetables, dairy products, and pharmaceuticals. According to the International Refrigerated Transportation Association (IRTA), the reefer shipping sector has seen a compound annual growth rate (CAGR) of 5.5% over the last decade, underscoring the increasing reliance on this method for maintaining the quality and safety of temperature-sensitive products.

The importance of reefer shipping containers is further emphasized by the fact that they help in reducing food waste worldwide. The Food and Agriculture Organization (FAO) estimates that approximately one-third of food produced globally is wasted, with a significant portion occurring during transportation due to inadequate temperature control. By utilizing reefer containers, businesses can extend the shelf life of products, ensuring they reach consumers while still fresh, which can enhance profitability and sustainability. As the demand for fresh produce and perishables continues to rise, the role of reefer shipping containers in enhancing food security and reducing waste cannot be overstated.

Temperature Stability During Reefer Container Transport

This chart illustrates the temperature stability in a reefer shipping container over the span of a week. The consistent temperature maintains the integrity of perishable goods during transport, highlighting the effectiveness of reefer shipping containers.

Key Features and Specifications of Reefer Containers

Reefer containers, also known as refrigerated shipping containers, play a crucial role in the transportation of temperature-sensitive goods. These units are engineered with advanced insulation and temperature control technologies to provide consistent temperatures ranging from -30°C to +30°C. According to industry reports, the global reefer container market is projected to reach approximately $7.8 billion by 2025, highlighting the increasing demand for safe and efficient transport of perishable items.

One of the key features of reefer containers is their high-performance cooling systems, which utilize either electric or alternative fuel sources to maintain the desired temperature. Modern reefer containers are equipped with precise temperature monitoring and control systems that allow for real-time data access, ensuring that the integrity of the cargo is maintained throughout the shipping process. Furthermore, the materials used in reefer container construction are designed to prevent condensation and minimize temperature fluctuations, which are crucial for maintaining product quality, especially during long-haul journeys.

In addition to temperature regulation, reefer containers boast various specifications designed for optimal loading and handling. They are available in different sizes, with 20-foot and 40-foot options being the most common. The International Maritime Organization estimates that over 60% of reefer cargo is transported via intermodal shipping, underscoring the versatility and adaptability of these containers in various logistical contexts. Employing reefer containers can significantly mitigate the risk of spoilage and loss, making them essential for industries ranging from food service to pharmaceuticals.

Best Practices for Loading and Securing Cargo in Reefer Containers

When it comes to transporting perishable goods, proper loading and securing of cargo in reefer shipping containers is critical. According to a report by the World Shipping Council, approximately 90% of the world’s goods are transported by the shipping industry, making the role of temperature-controlled containers indispensable in the logistics chain. To ensure optimal preservation and safety, it is important to adhere to best practices when using these containers.

One essential tip is to pre-cool the reefer container before loading. This practice stabilizes the internal temperature, ensuring that the cargo does not experience thermal shock. Additionally, shippers should load goods according to their temperature requirements, placing warmer items at the bottom and cooler items on top. This method not only promotes better air circulation but also helps maintain consistent temperatures throughout the cargo space, preventing spoilage.

Securing the cargo is just as important as proper loading. Use ratchet straps or cargo nets to hold items in place and prevent them from shifting during transit. According to the International Maritime Organization, improperly secured cargo can lead to significant damage and financial loss, with an estimated 60% of insurance claims in maritime shipping relating to cargo loss or damage. Ensuring that cargo is both well-loaded and secured minimizes risks associated with movement and temperature fluctuations, leading to safer transport outcomes.

Temperature Management Techniques During Transport

Effective temperature management is crucial when using reefer shipping containers to ensure that perishable goods remain intact during transport. Maintaining the appropriate temperature within the container not only preserves the quality of the cargo but can also prevent spoilage and financial losses. One of the primary techniques for optimal temperature management is pre-conditioning the cargo before loading. This involves acclimating the goods to the desired temperature, allowing the reefer container to effectively maintain the internal environment once the transport begins.

In addition to pre-conditioning, monitoring the temperature throughout the journey is essential. Modern reefer containers are equipped with advanced temperature control systems that provide real-time data. Utilizing these systems allows operators to make necessary adjustments in response to any fluctuations, ensuring that the temperature remains consistent. Regular checks and the use of temperature loggers can further enhance monitoring efforts, enabling quick identification and resolution of any issues that arise during transport. Together, these techniques play a pivotal role in safeguarding sensitive products, ensuring they reach their destination in optimal condition.

Essential Tips for Using Reefer Shipping Containers for Safe Transport - Temperature Management Techniques During Transport

| Temperature Management Technique | Effectiveness | Best Practices | Common Mistakes |

|---|---|---|---|

| Regular Calibration of Thermostats | High | Check weekly, document changes | Neglecting to calibrate before loading |

| Pre-cooling Containers | Medium | Cool containers for at least 2 hours | Loading warm products immediately |

| Use of Insulation Materials | High | Employ thermal blankets | Using substandard materials |

| Monitoring Temperature Logs | High | Review at each stop | Ignoring discrepancies in logs |

| Direct Airflow Orientation | Medium | Position cargo for optimal airflow | Blocking vents with cargo |

Safety Guidelines for Handling and Maintaining Reefer Containers

When handling reefer shipping containers, safety should be the top priority. These temperature-controlled units must be managed with care to ensure that the products they carry remain in optimal condition. It is essential to conduct thorough inspections before loading. Check for any signs of damage, leaks, or malfunctioning components that could compromise the cooling system. Ensuring that the container is clean and free of contaminants is also crucial, as this affects both safety and product integrity.

Proper training for personnel involved in the loading, unloading, and maintenance of reefer containers is vital. All team members should be well-versed in the specific protocols for operating the cooling systems and understand the importance of monitoring temperature levels throughout the shipping process. Regular maintenance checks should be scheduled to keep the refrigeration units functioning efficiently. Moreover, it's important to avoid overloading the container, as this can lead to inadequate airflow and temperature fluctuations that may spoil the cargo. By adhering to these safety guidelines, the risk of accidents and product loss can be significantly minimized, ensuring a more secure transport process.

Related Posts

-

Top 10 Benefits of Using Refrigerated Storage Containers for Your Business

-

Top 10 Sea Can Storage Solutions for Efficient Space Management

-

Maximizing Space with the Best 20 Storage Container Solutions for Every Home

-

10 Essential Tips for Choosing the Right Storage Shipping Containers

-

Eco-Friendly Choices: Transforming Second Hand Storage Containers into Stylish Organizers

-

Maximize Your Space: The Ultimate Guide to Choosing the Best 40 Storage Containers for Every Need

عربي

عربي عربي

عربي