News & Blogs

What is a Laboratory Sample Pulverizer and How Does it Work?

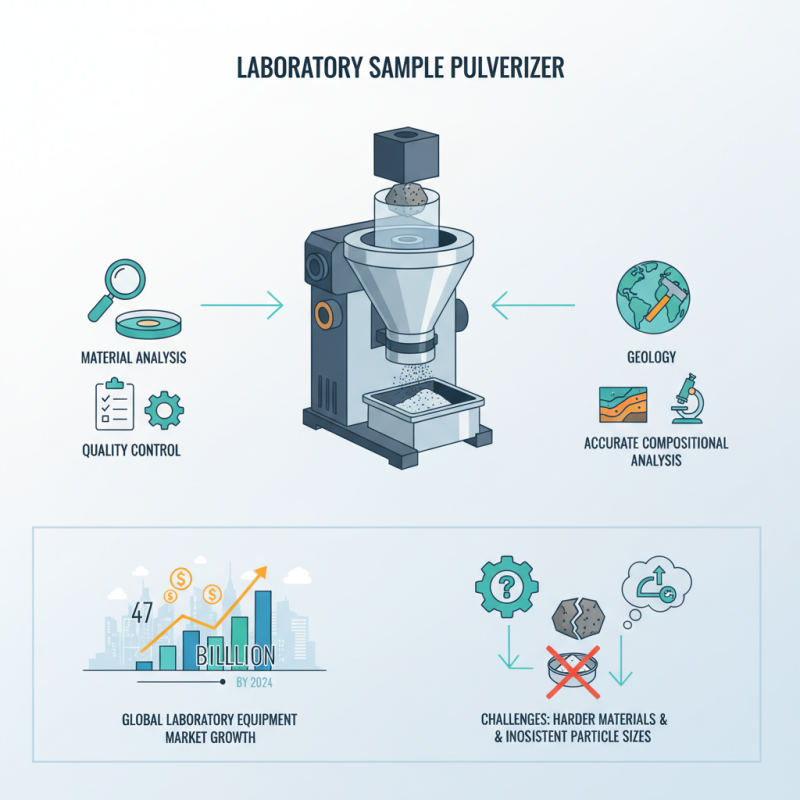

A laboratory sample pulverizer is a crucial tool in many industries. It is designed to reduce materials to a fine powder. This process is essential for various applications, including material analysis and quality control. According to industry reports, the global laboratory equipment market is projected to reach $47 billion by 2024. The demand for effective sample preparation tools is steadily increasing.

Many sectors rely on the precision of laboratory sample pulverizers. In geology, for example, samples must be finely ground for accurate compositional analysis. However, not all pulverizers are equally efficient. Some models may struggle with harder materials or produce inconsistent particle sizes. Professionals often face challenges when selecting the right equipment.

Despite advancements, there are still gaps in optimizing pulverization processes. Some users report that even high-quality pulverizers can fall short in reducing samples to the desired fineness. Improving these machines remains a focus for manufacturers. Continuous enhancements are necessary for meeting ever-evolving industry standards.

What is a Laboratory Sample Pulverizer?

A laboratory sample pulverizer is a machine designed to grind and pulverize materials into finer particles. Used extensively in various industries, it helps prepare samples for analysis. These devices are crucial in laboratories needing uniform particle sizes for accurate results. Different models exist, but they all share a common goal: achieving the desired consistency in sample preparation.

The working principle of a pulverizer is straightforward. It often uses mechanical forces to crush and grind the material. A rotating blade or pestle breaks the sample down. Users can adjust settings to achieve various mesh sizes. It's important to regularly inspect and maintain the equipment for optimal performance. Neglecting this can lead to inconsistent results or equipment failure. Additionally, sample contamination can occur if the pulverizer is not thoroughly cleaned between uses.

Laboratory sample pulverizers come in manual and automatic types. Each type has advantages and drawbacks. For example, automated devices offer higher precision, but manual ones allow for greater control of the grinding process. Users must consider their specific needs and resources when choosing. Balancing efficiency and accuracy can be challenging, and many laboratories continuously seek improvements.

The Importance of Pulverizers in Laboratory Settings

Pulverizers play a vital role in laboratory environments. They facilitate the preparation of samples by grinding materials into fine particles. This process enhances the accuracy of analytical testing. According to industry reports, the efficiency of sample processing can improve by 25% with the right pulverizer. In laboratories, even slight variations in sample size can lead to significant errors in results.

Furthermore, the choice of a pulverizer significantly impacts the quality of results. Different materials require distinct grinding techniques. For example, soft materials may need less energy than hard minerals. Statistics from a recent study indicate that improper grinding can result in up to 30% data inaccuracy.

Despite their importance, not all pulverizers meet laboratory standards. Some may create undesirable heat or dust. This can compromise the integrity of samples. Selecting a suitable model is critical. A thoughtful evaluation of lab needs ensures the effectiveness of sample preparation in achieving reliable results.

How Does a Laboratory Sample Pulverizer Operate?

A laboratory sample pulverizer is crucial for material processing in various fields. This machine reduces solid samples into fine powders. It operates by utilizing high-speed blades or rollers to crush materials. Often, samples are placed in a chamber where the grinding occurs. The size reduction is essential for accurate testing.

The pulverization process must be controlled. If not, operators may face discrepancies in sample size. For example, studies show that inconsistent particle sizes can alter test results by up to 20%. It's crucial for users to monitor the operation. Regular calibration helps maintain accuracy.

Not all pulverizers function the same way. Some use impact grinding, while others rely on friction. Each method has its pros and cons. Operators must decide which is best for their application. A poor choice could lead to inefficient processes or degraded sample quality. Understanding these differences is vital for effective sample analysis.

Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers come in various types, each suited for specific applications. One common type is the ball mill, which uses balls to crush materials into fine powders. This method is effective for brittle substances. Another type is the disc pulverizer, which employs two rotating discs to grind samples. Disc pulverizers are ideal for tougher materials.

Impact and jet mills also serve unique purposes. Impact mills break down samples through high-speed collisions, while jet mills use compressed air to achieve ultra-fine grinding. Each pulverizer has its strengths and weaknesses. For example, ball mills may not work well for very hard materials. In contrast, jet mills are often more suitable for heat-sensitive samples.

Choosing the right pulverizer is crucial. Users need to consider the sample type and desired particle size. This decision can impact the quality of analysis results, showing the importance of matching equipment to specific tasks. Making a thoughtful choice can improve efficiency and ensure reliable outcomes.

Laboratory Sample Pulverizer Performance Comparison

This chart compares the throughput of different types of laboratory sample pulverizers, demonstrating their efficiency in processing various materials. The data reflects average throughput measured in grams per minute (g/min) based on common laboratory usage.

Maintenance and Safety Tips for Using a Laboratory Sample Pulverizer

Using a laboratory sample pulverizer requires attention to maintenance and safety. Regular checks on the machine parts help ensure reliable performance. It’s crucial to clean the pulverizer after each use. Dust and debris can affect the quality of your samples. Regularly inspect blades and chambers for wear. Replace any damaged components promptly to avoid mishaps.

Safety is a primary concern when operating a pulverizer. Always wear appropriate personal protective equipment. This includes gloves, goggles, and a dust mask. Small particles can become airborne during operation. Ensure the workspace is well-ventilated to minimize inhalation risks. Don’t overlook the importance of proper training. Users should be familiar with the equipment’s operation and emergency procedures.

Sometimes, users may overlook small issues, thinking they are insignificant. This can lead to larger problems later. Document any irregularities you notice during use. Avoid taking shortcuts, and do not bypass safety features. A small lapse in attention can result in accidents. Always prioritize safety and clear rules in the lab. Take the time to reflect on your practices, and make adjustments when necessary.

عربي

عربي عربي

عربي