News & Blogs

Freight Container Tips for Efficient Shipping and Cost Savings

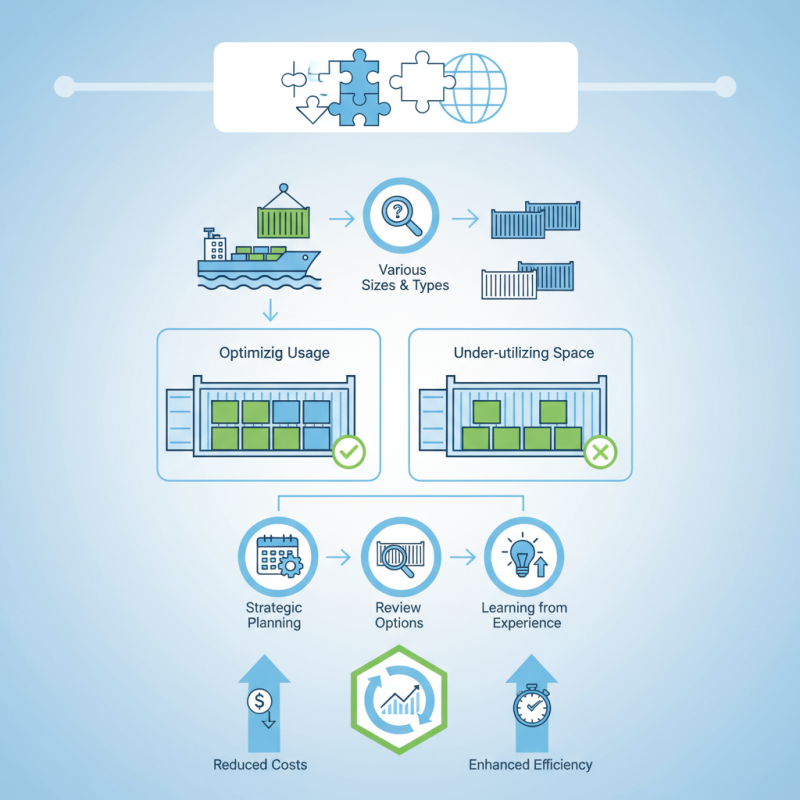

In the world of logistics, efficient shipping is vital. The use of freight containers has transformed the industry. Experts emphasize their importance. John Doe, a seasoned freight container specialist, once stated, “Optimizing container usage can drastically reduce shipping costs.” His insight underlines the need for strategic planning.

Freight containers come in various sizes and types. Choosing the right one makes a big difference. A common misstep is under-utilizing space. Shippers often overlook this detail. This oversight can lead to unnecessary expenses. Planning is essential but challenging.

Incorporating best practices can enhance efficiency. Regularly reviewing container options is key. There is no one-size-fits-all solution. Each shipment can pose unique challenges. Reflecting on past decisions can lead to improved strategies. Embracing flexibility and learning from experiences is crucial for success.

Choosing the Right Freight Container for Your Needs

Choosing the right freight container is crucial for efficient shipping. With over 90% of global trade transported by sea, proper selection directly impacts costs and delivery times. A report by the International Maritime Organization indicates that using the right container can improve shipping efficiency by up to 30%.

Consider the cargo type. Standard dry containers are common but may not suit all goods. Temperature-sensitive products require refrigerated containers, which can increase costs. Additionally, oversized items may need flat-rack containers, limiting stacking ability and space efficiency. Data shows that mismanaged container choices can result in increased shipping expenses of up to 20%.

Evaluating container conditions is vital. Checking for damage can prevent cargo loss and delays. Industry reports state that choosing a carrier with strict container maintenance standards reduces risk significantly. Think about container availability. If a wrong type is booked, it can lead to delays. Reflecting on these details can save time and money, making the shipping process smoother and more reliable.

Understanding Freight Container Sizes and Types

Choosing the right freight container is essential for efficient shipping. Containers come in various sizes and types. The most common are 20-foot and 40-foot containers. A 20-foot container can hold about 33 cubic meters. A 40-foot container offers nearly double that space. However, packing efficiency still matters.

Different types of containers serve unique purposes. For instance, refrigerated containers keep perishable goods fresh. Open-top containers allow taller items to be loaded easily. Yet, using the wrong type can lead to wasted space or damaged products. The selection process requires careful thought. Consider your cargo and its requirements.

The size and type of container impact shipping costs significantly. Oversized containers may lead to higher fees. On the other hand, a smaller container could increase the number of trips needed. Weigh all options before making a decision. Re-evaluating your container choice throughout the shipping process leads to better results. A thoughtful approach can save money and time.

Best Practices for Packing and Loading Containers

Packing and loading freight containers efficiently is crucial for maximizing space and reducing shipping costs. A well-packed container can save up to 30% in freight costs. According to industry reports, improper loading can lead to cargo damage, leading to significant financial losses. To avoid this, use standard loading patterns. Stack heavy items at the bottom, and lighter goods on top. Distribute weight evenly across the container.

Utilizing dunnage materials can prevent movement during transit. Wood, air bags, or foam can secure your cargo. Many companies overlook this step, thinking it adds unnecessary costs. However, ensuring that goods stay in place can reduce the risk of damage. Reports indicate that damage from poor loading can account for nearly 20% of shipping costs.

Consider the dimensions of your goods. Custom packaging can often lead to better space utilization. Still, it's essential to balance protection and weight distribution. Some businesses fail to measure their cargo accurately, resulting in wasted space. Data shows that every cubic meter not utilized means lost revenue. Regularly reviewing loading practices can lead to improved efficiency over time.

Cost-Saving Strategies for Shipping with Freight Containers

Shipping with freight containers can be cost-efficient when strategies are implemented wisely. Understanding various shipping routes helps avoid unnecessary detours. Researching carriers can reveal cheaper options. Compare costs, but remember that the lowest price may compromise service quality. Balance cost and reliability for optimal results.

Using standard container sizes can maximize space and reduce costs. Load containers efficiently to prevent wasted space. Consider using pallets to optimize loading. Packing strategies make a significant difference in shipping expenses. However, overloading can lead to fines. It's essential to find that sweet spot between cost and capacity.

Monitoring shipping trends also provides insights into cost-saving opportunities. Seasonal fluctuations can affect prices, making it vital to adapt. Additionally, keep track of fuel surcharges, as they fluctuate. Building relationships with transport partners may lead to discounts or improved service. Reflecting on past shipping experiences can lead to better decision-making in the future.

Freight Container Shipping Cost Savings

Tips for Tracking and Managing Your Freight Shipments

Tracking and managing freight shipments can seem daunting. However, a solid approach can make a big difference. Start by using a dedicated tracking software. These tools can provide real-time updates on your shipment's status. Knowing where your freight is at all times helps you stay informed. Missing updates can lead to misunderstandings and delays.

Communication with carriers is vital. Regularly check in for updates. If issues arise, address them quickly. Many companies struggle to maintain open lines with their shipping partners. Establish a routine for communication. Schedule calls or set reminders to reach out. This practice can prevent confusion later on.

Be mindful of documentation. Accurate paperwork reduces the risk of shipping errors. Mistakes can lead to financial losses and extra charges. Consistently review your documents. A simple oversight can cause headaches and delays. Learn from each shipment to improve your process. Tracking and managing shipments requires detail and attention, but it is necessary for success.

Related Posts

-

Top 10 Benefits of Using Cargo Containers for Shipping and Storage

-

Maximizing Space with the Best 20 Storage Container Solutions for Every Home

-

Innovative Uses of Sea Containers in Modern Sustainable Architecture

-

How to Transform a 40 Foot Shipping Container into Your Dream Home

-

10 Essential Tips for Choosing the Right Storage Shipping Containers

-

What is Cargo Storage Containers? A Complete Guide to Their Uses and Benefits

عربي

عربي عربي

عربي