News & Blogs

10 Essential Tips for Using a Reefer Shipping Container Effectively?

Using a reefer shipping container is crucial for transporting temperature-sensitive goods. These containers maintain precise temperatures, ensuring product freshness during shipping. However, effective use requires knowledge and careful planning.

Consider the importance of monitoring temperature settings regularly. A small oversight can lead to spoilage. It's also vital to pack the container properly. Poorly organized cargo can restrict air circulation and compromise temperature control.

Investing time in understanding the reefer’s components is essential. Many users neglect routine maintenance, which can lead to malfunctions. Remember, small details matter in the logistics of transporting perishables. Overall, effective use of a reefer shipping container enables safer and more efficient deliveries.

Understanding the Basics of Reefer Shipping Containers

Reefer shipping containers are vital in global trade. They keep perishable products fresh during transit. Typically, these containers maintain temperatures between -20°C to 20°C, depending on the cargo type. The World Shipping Council notes that temperature control can reduce spoilage by up to 30%. This highlights the importance of understanding the basics of these containers.

Operating a reefer requires attention to detail. Regular maintenance checks are critical. A malfunctioning unit can lead to damaged goods and losses. In 2022, industry reports indicated that 15% of reefer shipments experienced temperature deviations due to poor handling. This serves as a reminder that proper training and procedures are essential.

Moreover, planning the logistics of transportation is crucial. Knowing how long the cargo will be in transit allows for better temperature management. For instance, innovative technologies now provide real-time monitoring of conditions inside the container. However, many companies still rely on outdated methods. Investing in modern solutions can prevent costly mistakes and protect valuable shipments.

Choosing the Right Temperature Settings for Different Cargoes

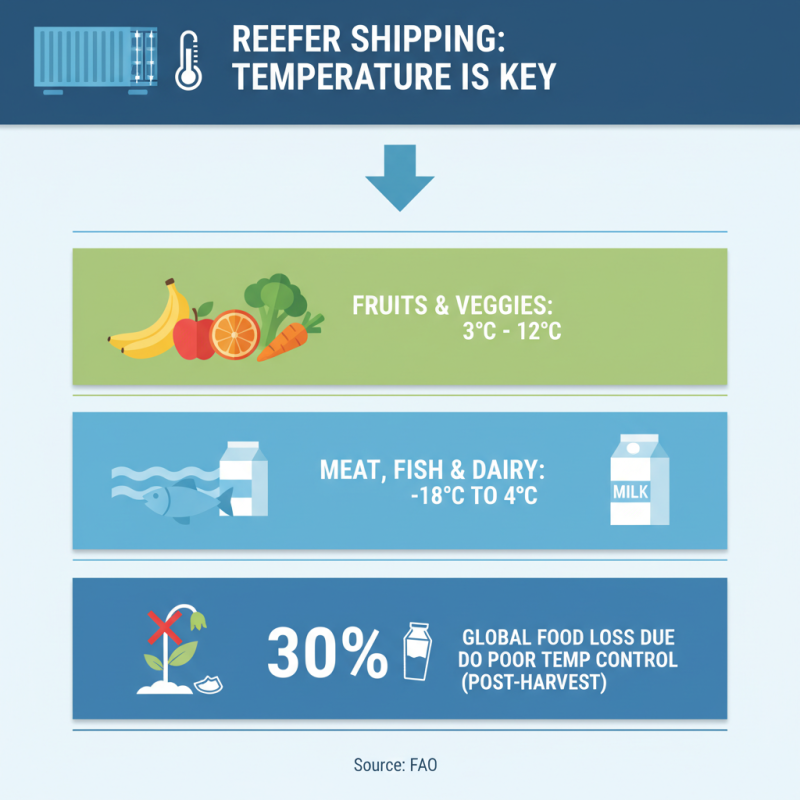

Choosing the right temperature settings for different cargoes in reefer shipping is critical. Maintaining the ideal temperature can prolong the shelf life of perishable goods. For instance, fruits and vegetables typically require temperatures between 3°C to 12°C. A study by the Food and Agriculture Organization states that 30% of perishable food is lost post-harvest due to improper temperature control.

For seafood, the perfect storage temperature is around -1°C to -2°C. When temperatures rise above this range, spoilage increases. Research indicates that seafood can lose quality within hours if not stored correctly. It’s essential to monitor temperature regularly to prevent such losses, using calibrated equipment for best results.

Dairy products generally thrive at temperatures around 0°C to 4°C. However, many operators overlook minor fluctuations. Even slight deviations can lead to spoilage. Data shows that a mere 1°C rise can decrease the shelf life by 10%. Reefer shipping requires constant attention to minimize these risks. Ignoring these details could mean significant financial losses and dissatisfaction for clients.

Packing Techniques to Optimize Space and Maintain Temperature

Packing a reefer shipping container effectively requires careful consideration of space and temperature maintenance. According to industry reports, improper packing can lead to spoilage rates exceeding 25% for sensitive goods. Thus, using space wisely is crucial.

Start by using stacking techniques. Place heavier items at the bottom and lighter items on top. This prevents crushing and airflow obstruction. Use dunnage or air pillows to fill voids. With better airflow, temperature consistency improves, helping maintain the cool chain.

Tip: Always monitor the temperature settings before loading. A discrepancy of even a few degrees can spoil perishables. Regularly check seals and insulation to avoid cold air leaks. Data indicates that 15% of reefer fails come from insulation issues.

Consider using thermal blankets for extra protection. They can minimize temperature fluctuation during transport. Lastly, remember that overloading can disrupt airflow, leading to condensation and spoilage. So, don't just fill every inch; leave room for air circulation.

10 Essential Tips for Using a Reefer Shipping Container Effectively

| Tip No. | Tip Description | Packing Technique | Temperature Management |

|---|---|---|---|

| 1 | Check and maintain the refrigeration unit | Ensure proper airflow | Set appropriate temperature before loading |

| 2 | Use pallets for easy loading and unloading | Elevate products off the floor | Avoid direct contact with container walls |

| 3 | Load items efficiently | Maximize vertical space | Ensure even temperature distribution |

| 4 | Ventilate properly to avoid moisture | Leave space between packed items | Control humidity levels |

| 5 | Use temperature monitoring devices | Install sensors on various levels | Track temperature fluctuations |

| 6 | Plan for loading and unloading times | Organize shipments by temperature needs | Limit exposure to warm air |

| 7 | Seal the container properly | Use proper packing materials | Prevent temperature loss due to leaks |

| 8 | Regularly train staff on best practices | Simulate loading scenarios | Emphasize importance of temperature control |

| 9 | Inspect regularly for damage | Check for insulation issues | Schedule routine maintenance |

| 10 | Know the limits of your reefer | Avoid overloading | Understand capacity and temperature range |

Regular Maintenance and Inspection for Efficient Operation

Regular maintenance and inspection play a crucial role in the effective operation of reefer shipping containers. Data from the International Maritime Organization indicates that improper maintenance can lead to a 20% increase in energy consumption. This inefficiency not only affects costs but can also compromise the cargo quality. Checking the refrigerant levels and ensuring proper insulation can prevent significant loss during transit.

Moreover, frequent inspections help identify potential issues before they escalate. A study by the Global Cold Chain Alliance reported that 30% of reefer containers face temperature fluctuations due to minor malfunctions. Simple tasks, like cleaning the air vents and verifying that gaskets are in good condition, can alleviate these problems. Neglecting these checks may result in unexpected delays, increased operational costs, and compromised cargo integrity.

It is essential to develop a scheduled maintenance routine. Skipping routine checks might seem convenient, but it creates extensive risks. Establishing procedures ensures that any irregularities are caught early. Ultimately, keeping a reefer container in top shape is not just about compliance; it reflects on the business's commitment to quality and customer satisfaction.

Reefer Shipping Container Utilization: Monthly Temperature Ranges

Best Practices for Loading and Unloading Reefer Containers

When loading a reefer container, the arrangement of cargo is crucial. Use sturdy pallets to stabilize the load. Stack items uniformly to prevent shifting during transport. Make sure to leave space for airflow. Refrigerated containers rely on good circulation to maintain temperature. If items are packed too tightly, cold air cannot circulate effectively. This can lead to spoilage.

Unloading requires careful attention as well. Open the doors slowly to prevent sudden temperature changes. Always check the temperature before taking items out. It’s tempting to rush, but haste can result in damaged goods. Also, consider the sequence of unloading. Take out the oldest items first. This reduces waste and ensures freshness. Remember, temperatures can fluctuate even during unloading, so be mindful.

Reflect on your procedures. Are you using the right techniques? Are the workers trained properly? One mistake can lead to significant losses. Regularly audit your processes. Improvement is always possible in the world of reefer shipping.

Related Posts

-

How to Choose the Right Reefer Shipping Container for Your Needs?

-

2025 Top 10 Best 40 Storage Containers for Ultimate Organization and Efficient Space Management

-

Top Uses for a 40 Foot Shipping Container for Storage and Transport

-

How to Choose the Right Shipping Containers for Your Needs

-

10 Essential Tips for Choosing the Right Sea Can Container

-

Top 10 Benefits of Using Refrigerated Containers for Your Cold Chain Logistics

عربي

عربي عربي

عربي