News & Blogs

10 Essential Tips for Using Reefer Containers Effectively

In the world of logistics, effectively using a reefer container is crucial for preserving temperature-sensitive goods. Renowned logistics expert Dr. Sarah Adams states, "The key to successful reefer transportation lies in understanding its operational nuances." Her insights emphasize the importance of proper practices in this specialized area.

Reefer containers maintain specific temperatures, ensuring quality during transit. However, many shippers overlook vital aspects. They often neglect to monitor temperature fluctuations frequently. This can compromise the integrity of their cargo. Regular audits of the container's condition are essential. Even minor oversights can lead to significant losses.

Maintaining a reefer container is more than just setting the thermometer. It involves a detailed understanding of insulation, air circulation, and power supply. Shippers should invest in training their staff. Friction can occur due to improper loading or incorrect temperatures. This can leave room for improvement in an industry that must adapt to new challenges. Failing to refine these practices may lead to unfortunate consequences.

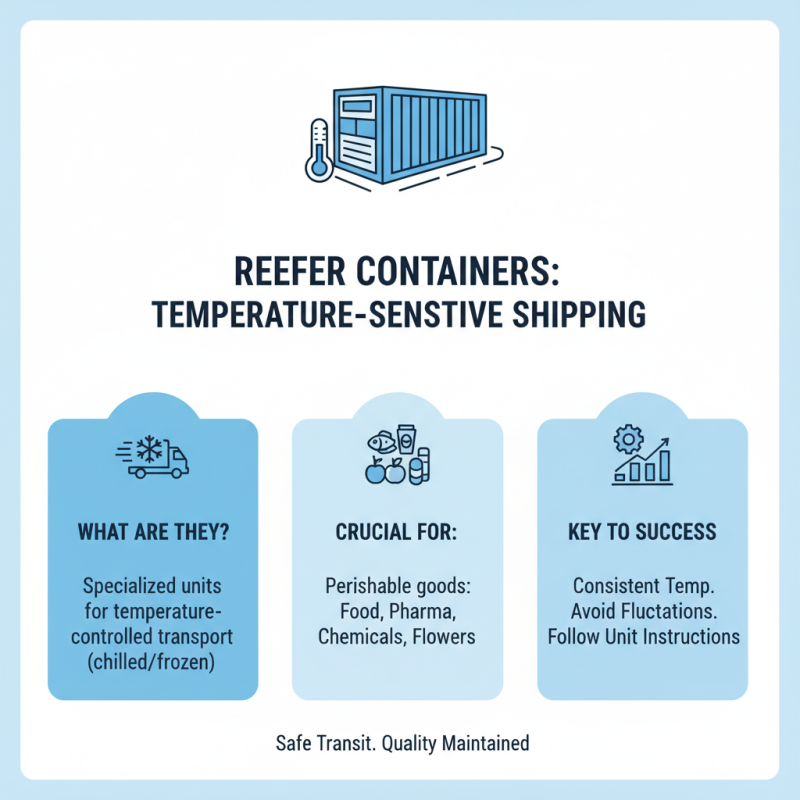

Understanding Reefer Container Basics for Safe Transportation

Reefer containers are specialized equipment for transporting temperature-sensitive goods. They keep products at consistent temperatures, ranging from chilling to freezing. Proper understanding of these containers is crucial to ensure safe transportation. Temperature fluctuations can lead to spoilage. It's essential to familiarize yourself with the operating instructions specific to each reefer unit.

Monitoring is critical during transit. Regularly check the temperature settings and alarms. Small deviations can have serious implications, especially for perishable items. Also, consider the placement of goods inside the container. Overpacking can obstruct airflow. This can lead to uneven temperatures and potential spoilage.

Don't underestimate the importance of maintenance. Regular checks and servicing can prevent unexpected breakdowns. Even minor issues can escalate quickly in transit. Understand the limitations of your reefer container. Sometimes, relying too heavily on technology can backfire. It’s wise to stay vigilant and adaptable to changing conditions during transportation.

Selecting the Right Reefer Container for Your Cargo Needs

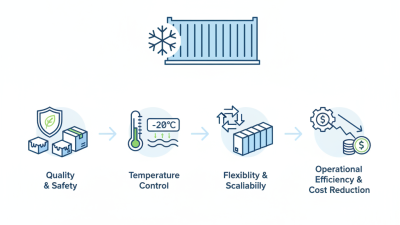

Selecting the right reefer container is crucial for preserving the quality of temperature-sensitive cargo. Before making a choice, consider the type of goods you will transport. Fresh produce, pharmaceuticals, and frozen items all have unique requirements. For instance, fruits may need a higher humidity level, while vaccines require stable, low temperatures. Each detail matters in maintaining integrity during transit.

Also, think about the size and capacity of the container. A too-small container can lead to overheating, while an oversized one may increase shipping costs. If you’re unsure, consult with logistics experts. They can provide insights tailored to your cargo specifics.

Lastly, don't overlook proper insulation in the reefer. It plays a vital role in energy efficiency. Regular maintenance is another aspect often neglected. Failing to check for leaks or mechanical issues can compromise the entire shipment. Keep a close eye on these factors to ensure a smooth shipping process and avoid costly mistakes.

Optimal Temperature Settings for Different Types of Goods

When it comes to using reefer containers for transporting goods, temperature settings are crucial. Different products require specific conditions for optimal preservation. For example, seafood thrives at around -18°C. This temperature helps maintain freshness, preventing spoilage. On the other hand, fruits need warmer temperatures, typically between 0°C and 2°C. For bananas, exposure to cold can ruin their texture and flavor, leading to losses.

It's essential to monitor and adjust settings consistently. Technical failures may occur, leading to temperature fluctuations. These changes can impact the quality of the goods. Regular checks can help catch such issues early. Some goods, like pharmaceuticals, have strict requirements. They often need a stable range of 2°C to 8°C. Ignoring these specifics can lead to compromised efficacy.

Sometimes, crew members may forget to document temperatures. This oversight could result in financial losses. Different goods can behave unpredictably under various conditions. Proper training and awareness about these factors are necessary. Being knowledgeable about the right temperature settings can save time and resources in the long run. Overall, the focus should be on remaining vigilant and responsive to the needs of each product transported in a reefer container.

10 Essential Tips for Using Reefer Containers Effectively - Optimal Temperature Settings for Different Types of Goods

| Type of Goods | Optimal Temperature (°C) | Humidity Level (%) | Storage Duration (Days) |

|---|---|---|---|

| Fresh Fruits | 1 to 4 | 85-90 | 7-14 |

| Vegetables | 0 to 2 | 90-95 | 7-21 |

| Meat | -1 to 2 | 85-90 | 5-10 |

| Seafood | -1 to 0 | 85-90 | 1-3 |

| Dairy Products | 0 to 4 | 85-90 | 7-14 |

| Pharmaceuticals | 2 to 8 | 50-60 | 30-90 |

| Chocolate | 15 to 18 | 50-60 | 30-90 |

| Beverages | 0 to 4 | 85-90 | 7-14 |

| Flowers | 0 to 2 | 90-95 | 5-10 |

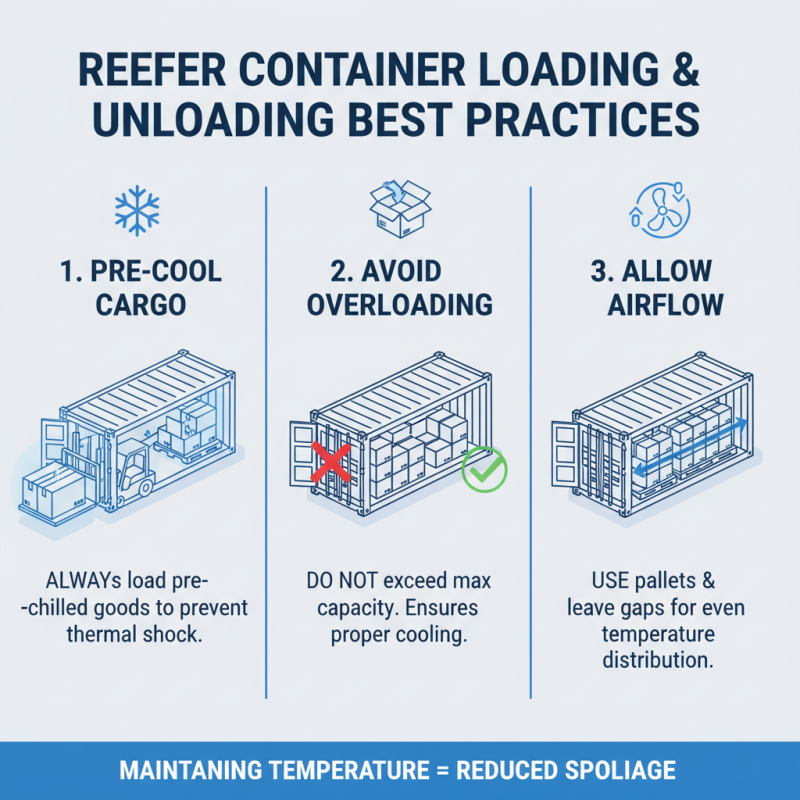

Proper Loading and Unloading Techniques to Maintain Temperature

Proper loading and unloading techniques are critical for maintaining the temperature in reefer containers. Always ensure that the cargo is pre-cooled before loading. This prevents thermal shock to the cooling system. Overloading can overwrite cooling capabilities and lead to spoilage. Use pallets to allow air circulation, ensuring even cooling throughout the container.

When unloading, do it quickly. Limit the time the container door is open. Every second counts. Rapid temperature changes can jeopardize the cargo. Always monitor the temperature during unloading. If discrepancies arise, address them immediately. Check that the cargo hasn’t shifted during transport. Follow best practices consistently; mistakes can lead to expensive losses.

It's easy to overlook small details, but they matter. For example, inspect gaskets regularly. If they wear out, cold air escapes. Also, ensure vents are not blocked. Neglecting these elements could result in poor performance. Observe and adjust practices as needed; even experienced handlers continually learn. Each load is an opportunity to refine methods further.

Regular Maintenance and Monitoring for Reefer Container Efficiency

Regular maintenance is crucial for the efficient operation of reefer containers. Checking the refrigeration unit regularly can prevent many issues. Monitoring the temperature settings is essential. Even a slight fluctuation can spoil sensitive cargo. Inspect the gaskets for wear and tears. A damaged seal may cause temperature loss.

Another important aspect involves monitoring the power supply. Any interruption can lead to product spoilage. Ensure that backup power options are available for emergencies. Regular cleaning of the interior helps maintain hygiene. Residual spills or debris can create odorous environments. It’s also helpful to keep a log of maintenance checks. This practice improves accountability and efficiency.

Sometimes, even with strict routines, problems arise. Equipment can malfunction unexpectedly. Operators must be prepared and adaptable. Training staff to respond swiftly is vital. Regular sharing of maintenance experiences can also enhance operations. Reflecting on past issues often leads to better preventive measures. Emphasizing teamwork in routine checks builds a proactive culture.

Reefer Container Maintenance and Efficiency Metrics

Related Posts

-

Essential Tips for Using Reefer Shipping Containers for Safe Transport

-

Top 10 Benefits of Using Refrigerated Containers for Your Cold Chain Logistics

-

Top 10 Benefits of Using Refrigerated Storage Containers for Your Business

-

Why Choose a Refrigerated Storage Container for Your Business Needs

-

How to Choose the Right Cargo Shipping Container for Your Needs?

-

How to Choose the Right Sea Container for Your Shipping Needs

عربي

عربي عربي

عربي