News & Blogs

2026 Best Reefer Container Options for Shipping Companies?

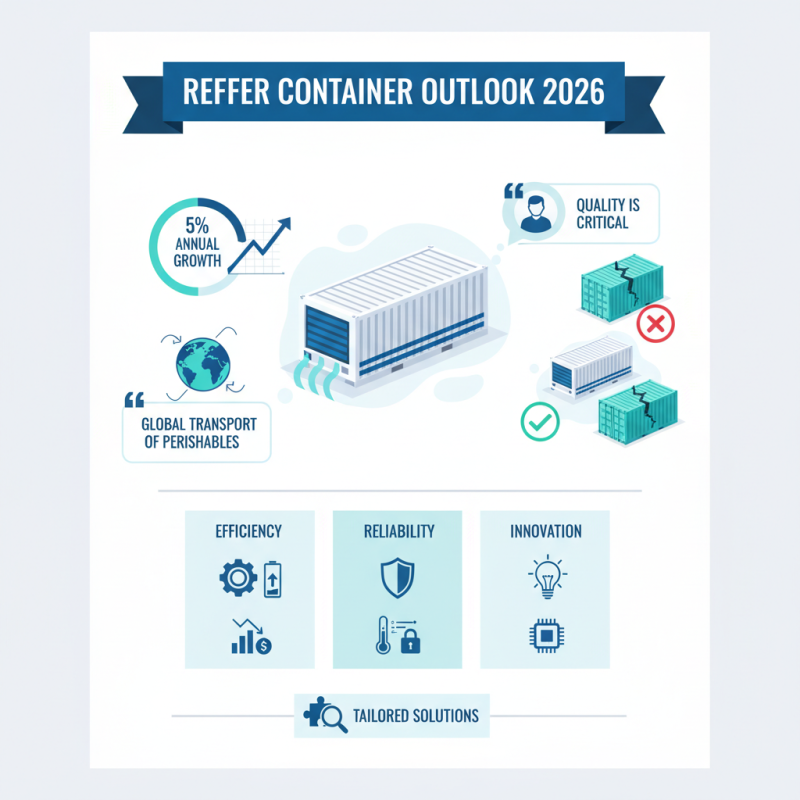

In the world of shipping, reefer containers play a critical role. These temperature-controlled units transport perishable goods globally. According to the Global Reefer Container Market Report 2023, the demand for reefer containers is expected to grow by 5% annually. This highlights the importance of reliable cooling solutions for shipping companies.

Industry expert, John Smith, emphasizes, "Choosing the right reefer container is essential for maintaining product quality." His insight reflects a concern that not all containers meet high standards. Some shipping companies opt for cheaper options, risking spoilage of valuable cargo.

As competition increases, the reefer container market must adapt. Companies need to prioritize efficiency and reliability. Innovative technologies will enhance performance and lower costs. However, finding the best reefer container solutions is not straightforward. It requires careful evaluation and consideration of each company's unique needs.

Overview of Reefer Containers and Their Importance in Shipping

Reefer containers are essential in the shipping industry. They are specially designed to transport perishable goods. This includes fruits, vegetables, and pharmaceuticals. The ability to maintain a consistent temperature is crucial. It helps to extend the shelf life of products during transit. A malfunctioning reefer can lead to significant losses.

The importance of these containers cannot be overstated. With global trade increasing, the demand for refrigerated shipments rises. Shipping companies must ensure their equipment is up to date. Old units may not regulate temperature effectively. Regular maintenance is vital. It prevents unexpected breakdowns.

Choosing the right options can be overwhelming. Some containers may not fit all needs. Size and efficiency are key factors. Companies often have to balance cost and quality. It’s not easy to find a perfect match. Many companies face challenges in meeting strict regulations. Reefer containers must comply with various standards. This adds another layer of complexity to decision-making. Careful consideration is necessary for success.

Key Features to Look for in Reefer Containers for Optimal Performance

When choosing reefer containers, it’s vital to focus on features that enhance performance. One key aspect is temperature control. Look for units with precise temperature regulation. This ensures your goods remain stable throughout their journey. Additionally, efficient insulation is crucial. Quality insulation minimizes energy use while preserving internal temperatures. Good insulation also reduces condensation, protecting cargo quality.

Durability matters too. Containers should withstand harsh conditions. Rust resistance and robust construction help prolong their lifespan. Consider the type of cargo you’ll ship. Some containers come equipped with adjustable shelves or flexible layouts. This adaptability can optimize space and enhance packing efficiency.

**Tip:** Regularly check seals and gaskets. A small air leak can ruin perishable items.

Monitoring technology is another feature worth exploring. Real-time temperature and humidity tracking can prevent issues before they escalate. These systems can alert you to deviations, allowing for quick action. It’s a modern approach, but not all companies adopt it. A lack of monitoring could lead to regrets later.

**Tip:** Invest in training your staff on container operation. Proper handling reduces potential mistakes.

Top Brands and Models of Reefer Containers in 2026

In 2026, the reefer container market offers various top options for shipping companies. These containers are essential for transporting perishable goods. According to industry reports, the demand for refrigerated containers is expected to grow by 5% per year through 2028. This growth is due to the increasing need for cold chain logistics.

Several models are highly regarded this year. Innovations in energy efficiency and insulation have improved temperature control. Containers now also have advanced monitoring systems. These features ensure the preservation of cargo quality during transit. However, some models are still prone to technical issues. Shipping companies often report challenges with maintenance and repair. This can lead to unexpected downtime.

Tips: When selecting a reefer container, consider energy efficiency ratings. Look for models with robust monitoring features. Efficiency can reduce operational costs significantly. Also, ensure that the model you choose has readily available parts for maintenance. This helps avoid prolonged service interruptions. Researching user reviews can be beneficial, but always consider the context. Some feedback may stem from unique operational challenges rather than product flaws.

Cost Considerations for Shipping Companies When Choosing Reefer Options

Cost is a critical factor for shipping companies when selecting reefer containers. The initial investment in reefer technology can be substantial. Reports indicate that the average cost of a new reefer container ranges from $3,000 to $6,000. Leasing is also an option, but monthly fees can add up quickly.

In addition to the upfront cost, ongoing expenses play a significant role. Energy consumption is a major concern. According to recent industry studies, reefer containers can consume up to 30% more energy than standard containers. This translates into higher operational costs. Shipping companies must also consider maintenance costs. Regular servicing and repairs can accumulate, especially for high-use containers.

While reefer containers offer essential benefits, including temperature control, the financial burden is evident. Companies often face difficult decisions. They must balance quality and cost-efficiency. The choice of advanced insulation and efficient refrigeration systems can mitigate some energy costs. However, these upgrades typically require higher initial spending. Shipping companies need to reflect on their financial strategies and choose wisely to sustain profitability in a competitive market.

Future Trends and Innovations in Reefer Container Technology

The future of reefer container technology looks promising. Innovations are emerging to enhance temperature control and energy efficiency. Advanced insulation materials can minimize energy loss, keeping goods fresh for longer. Moreover, real-time monitoring systems are becoming standard. They track temperature and humidity, ensuring optimal conditions during transit.

Tips for shipping companies: Invest in training for your staff on new technologies. Understanding how to use digital tools effectively can prevent mishandling. Regular maintenance of reefer containers is essential. A small issue can lead to larger problems.

Sustainability is also a key focus. Eco-friendly refrigerants are being developed to reduce environmental impact. However, not all options may be reliable. Companies must evaluate their choices carefully. The challenge remains in balancing cost with innovation. Adopting new technologies often involves risk. Understanding these risks is crucial for the shipping industry's future.

2026 Best Reefer Container Options for Shipping Companies

| Container Type | Temperature Range (°C) | Capacity (cu ft) | Energy Efficiency Rating | Innovative Feature |

|---|---|---|---|---|

| Standard Reefer | -30 to 30 | 40 | A+ | Real-time temperature monitoring |

| Multi-Temperature Reefer | -30 to 25 | 45 | A | Divided compartments for different products |

| Integrated Reefer | -40 to 30 | 50 | A++ | Self-contained power system |

| Specialized Reefer for Pharmaceuticals | 2 to 8 | 30 | A++ | Automated temperature adjustment |

| Smart Reefer | -20 to 25 | 45 | A++ | IoT connectivity for fleet management |

Related Posts

-

Essential Tips for Using Reefer Shipping Containers for Safe Transport

-

10 Essential Tips for Using Reefer Containers Effectively

-

Top 10 Benefits of Using Refrigerated Storage Containers for Your Business

-

Top Standard Shipping Container Sizes Explained?

-

2026 Best Container World Innovations and Trends to Watch?

-

40 Best Uses for a 40 ft Storage Container in Your Business or Home?

عربي

عربي عربي

عربي