News & Blogs

2026 Top Trends in Reefer Shipping Containers What to Expect?

In the rapidly evolving world of logistics, reefer shipping containers hold a pivotal role. These specialized containers ensure the safe transport of temperature-sensitive goods. As we look towards 2026, several trends are likely to shape this industry. The demand for fresh produce and pharmaceuticals is rising. This, in turn, pushes the need for more efficient reefer shipping containers.

Innovations in technology will also transform how these containers operate. For instance, advances in insulation materials can enhance temperature control. Moreover, Internet of Things (IoT) sensors will provide real-time monitoring. However, the industry must address challenges like energy consumption and sustainability. Reefer shipping containers may be more efficient, yet they still consume significant energy.

As the logistics landscape changes, it’s essential to remain adaptable. Reefer shipping container designs could evolve to meet varying regulations worldwide. Trends are exciting but often require reflection on best practices. Keeping pace with demands and innovations is not easy. Balancing efficiency and sustainability remains a constant challenge.

Future Innovations in Reefer Shipping Container Technology

Reefer shipping containers are evolving rapidly. Innovations are transforming how perishable goods are transported. Industry reports forecast that the reefer market will grow by 7% annually by 2026. New technologies are enhancing efficiency and sustainability in shipping.

One exciting development is the integration of IoT devices in reefer containers. These devices monitor temperature and humidity in real-time. This ensures that goods remain fresh during transit. According to a recent study, using IoT can reduce spoilage by up to 15%. Shippers can make data-driven decisions to improve operations and reduce waste.

Tips: Regular maintenance of reefer units is crucial. Even minor issues can lead to spoilage. Monitor data closely to catch changes early. Consider investing in training for your team on new technologies. This approach can ultimately save money and improve service.

Sustainability is another vital trend. Many companies are adopting eco-friendly materials for reefer construction. Reports indicate that using lightweight materials can cut fuel consumption by 20%. However, challenges remain in balancing cost and sustainability. Companies must reflect on their environmental impacts while remaining competitive.

2026 Top Trends in Reefer Shipping Containers

This chart illustrates the anticipated trends in reefer shipping containers for 2026, highlighting key areas such as sustainability innovations, advanced temperature control technology, and energy efficiency improvements. Each trend is rated on a scale from 1 to 10 based on its expected impact in the industry.

Sustainability Trends and Their Impact on Reefer Shipping

Sustainability is reshaping reefer shipping in 2026. Industry reports show that 70% of logistics companies prioritize eco-friendly practices. This shift responds to growing global concerns about climate change and resource depletion. Companies are increasingly adopting energy-efficient technologies. These advancements can reduce carbon emissions by up to 25%.

Reefer containers are now designed with sustainable materials. They even include insulation made from recycled products. This technology helps maintain temperature while using less energy. Yet, challenges remain. Many companies still struggle with upfront costs. The investment in sustainable fleets can be high.

Moreover, regulations are tightening worldwide. The International Maritime Organization has set ambitious targets for reducing emissions. Companies must adapt fast or risk penalties. However, innovation continues to bloom. Some firms are experimenting with solar-powered reefer units. This approach may offer a glimpse into a greener future. Yet, widespread adoption is not imminent. The path ahead demands commitment and investment.

2026 Top Trends in Reefer Shipping Containers What to Expect?

| Trend | Description | Impact on Reefer Shipping | Sustainability Aspect |

|---|---|---|---|

| Energy-efficient Refrigeration | Adoption of higher efficiency refrigeration systems | Reduced energy consumption and costs | Lower carbon footprint through energy savings |

| IoT and Smart Containers | Integration of IoT technology for monitoring | Enhanced tracking and efficiency in logistics | Better resource management and waste reduction |

| Biodegradable Insulation | Usage of eco-friendly insulation materials | Improved thermal performance and lower environmental impact | Less landfill waste and reduced resource extraction |

| Solar-Powered Containers | Containers equipped with solar panels | Lower reliance on fossil fuels for refrigeration | Promotion of renewable energy use |

| Recycling Programs | Initiatives for repurposing and recycling containers | Reduction of overall waste generated | Supports circular economy principles |

Evolving Temperature Control Systems for Perishable Goods

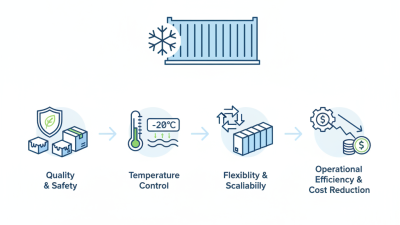

The reefer shipping container industry is evolving rapidly, with advanced temperature control systems becoming essential for transporting perishable goods. A recent report from the International Maritime Organization (IMO) shows that the demand for refrigerated transport is expected to grow by 25% by 2026. With food waste being a major concern globally, better temperature management in shipping is critical.

New technologies are emerging to enhance the precision of temperature controls in shipping containers. Smart sensors can monitor and adjust conditions in real-time. This innovation ensures that cold chain integrity is maintained throughout the shipping process. However, challenges remain. Issues can arise due to unreliable power sources during transport, risking spoilage. A report from the Food and Agriculture Organization (FAO) states that 1/3 of food produced is lost or wasted. It underscores the need for more robust systems that ensure consistent temperature during transit.

Tips: Regular maintenance of temperature control systems is vital. Ensure that all equipment is calibrated correctly. Create contingency plans for potential power outages. Educating staff on best practices can also mitigate risks. Keeping abreast of industry advancements can help adapt to changing regulations. Staying informed leads to improved efficiency in the supply chain.

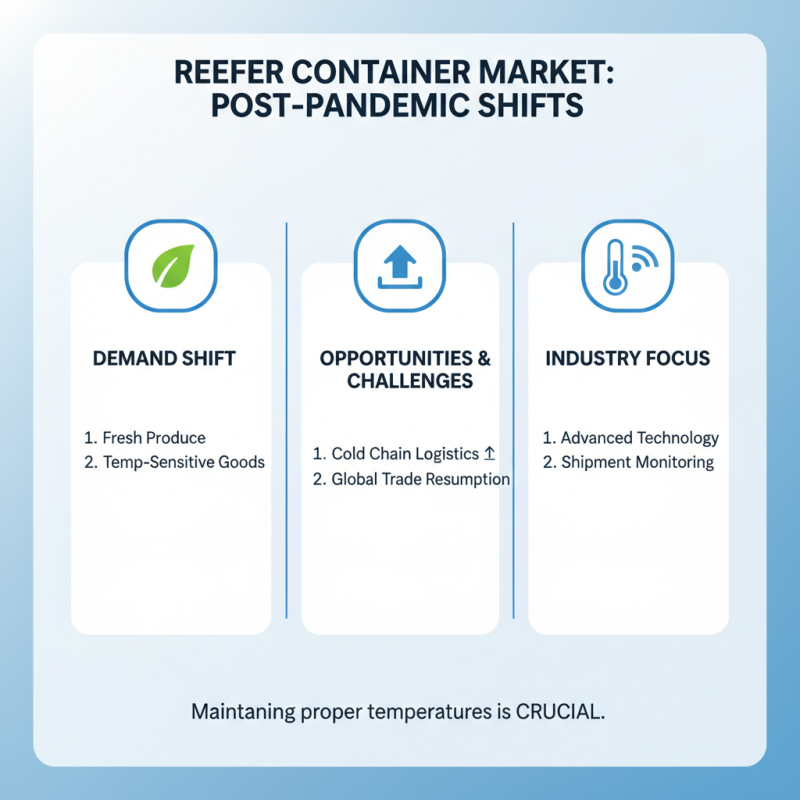

Market Demand Shifts: Reefer Containers in Post-Pandemic Trade

The demand for reefer containers has changed significantly after the pandemic. Businesses are now focusing on fresh produce and temperature-sensitive goods. This shift offers both opportunities and challenges for the industry. Cold chain logistics have become more crucial than ever. As global trade resumes, maintaining proper temperatures during transport is essential. Companies investing in advanced technology for monitoring shipments are finding an edge.

However, the supply chain is still not perfect. Disruptions can still occur, impacting delivery times. Many companies struggle to adapt to rapidly changing demands. Capacity issues can arise, leading to delays and increased costs. This is a time for reflection on operational efficiencies and flexibility. Reefer container management systems are evolving, but often they fall short of expectations.

Furthermore, sustainability concerns are growing. Consumers are increasingly aware of environmental impacts. The industry must consider more eco-friendly practices. Switching to sustainable refrigerants is one step, but not the only one. Reefer shipping must embrace innovation to meet future demand. While opportunities abound, it’s vital to address the existing imperfections in the system.

Emerging Regulations and Standards for Reefer Shipping Containers

In the reefer shipping industry, emerging regulations are reshaping standards for temperature-controlled containers. According to a report by the Global Container Shipping Association, over 40% of perishable goods need refrigeration during transit. As demand grows, stricter compliance measures are required. This means shippers must adapt quickly.

New guidelines aim to enhance energy efficiency and reduce emissions. The recent International Maritime Organization (IMO) regulations target a 40% reduction in greenhouse gas emissions by 2030. Reefer containers, which currently consume significant energy, face increasing scrutiny. Upgrading to systems that align with these standards is essential but often costly.

Digital monitoring is becoming commonplace, allowing real-time tracking of container conditions. However, many shippers struggle with technology integration. Some systems are outdated or lack proper training. Without timely updates, the risk of spoilage increases. Despite the challenges, failure to comply with these new standards could lead to hefty fines and loss of cargo.

Related Posts

-

Essential Tips for Using Reefer Shipping Containers for Safe Transport

-

10 Essential Tips for Using Reefer Containers Effectively

-

2026 Best Reefer Container Options for Shipping Companies?

-

How to Transform a 40 Foot Shipping Container into Your Dream Home

-

Top 10 Benefits of Using Refrigerated Containers for Your Cold Chain Logistics

-

Why Choose a Refrigerated Storage Container for Your Business Needs

عربي

عربي عربي

عربي